Rubber Cutting Edges

Laminated rubber cutting edges are used to prolong the wear life of concrete tipping floors.

Laminated rubber cutting edges are used in Transfer Stations, Recycling Facilities and Waste-to-Energy Plants to prolong the wear life of concrete tipping floors. The cost of repairing and replacing a tipping floor can put a strain on the maintenance budget – not to mention the operational downtime associated with the repairs.

Application

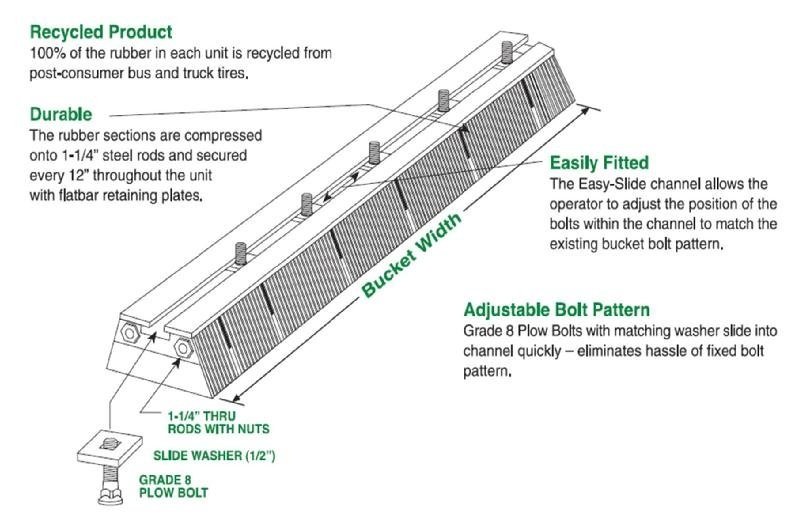

Each cutting edge is built to accommodate a specific bucket size – if you provide us with a few dimensions we'll produce and ship your custom edge within a few days. We also keep eight general sizes in stock. All of our rubber cutting edges have an innovative sliding, T-track mounting channel.

Shapes and Sizes

Outlasts a molded cutting edge 2:1

Easy to mount with our T-Track channel

100% recycled laminated rubber and recycled steel

Squeegee effect for pushing liquids

On-site stock in 8 sizes for next day shipment

Benefits:

911X

With 8" of wear surface and a reversible profile, the 911x is designed for heavy-duty materials like metal, glass, and construction debris.

911T

With 6" of wear surface, it's one of our most versatile rubber cutting edges. Where scooping and loading applications are more critical than pushing.

911R

With 6" of wear surface and a reversible profile, the 911r is designed for heavy-duty wheel loaders. Designed for pushing and tamping applications.

911M

With 3" of wear surface and a rounded profile, the 911m is suitable for mid-size wheel loaders and backhoes.

911S

The 911s is our smallest edge, but it's incredibly tough. Its 2" of wear surface helps skid steers get the job done.